- Description

- Specification

- Delivery

HVS boilers are for the combustion of untreated, split, wood logs with a log length from 33 up to 100 cm according to boiler size.

You can choose between two different designs, either with lambda control (HVS LC) or without (HVS E).

The boilers are available with a nominal heat output in 16, 25, 40, 60 and 100 kW.

Just fill in logs, light the wood and everything else is working fully automatically. The large fuel chamber provides a long combustion period. The integrated fan guarantees an unproblematic start. The heating up flap and its safety door lock do not give way for smoke emission. Moreover, the combustion is stabilized throughout the whole combustion period by the fan and enables an unproblematic operation. Even the boiler size with 25kW can comfortably be filled with 0,5m logs through the large fuel chamber door. An overlength of the logs is, at least to some extent, no problem due to the depth of the fuel chamber. Long refueling intervals are the result of the large filling capacity. An increase in performance and very good exhaust gas values are achieved by a „hot air duct“ inside the tank.

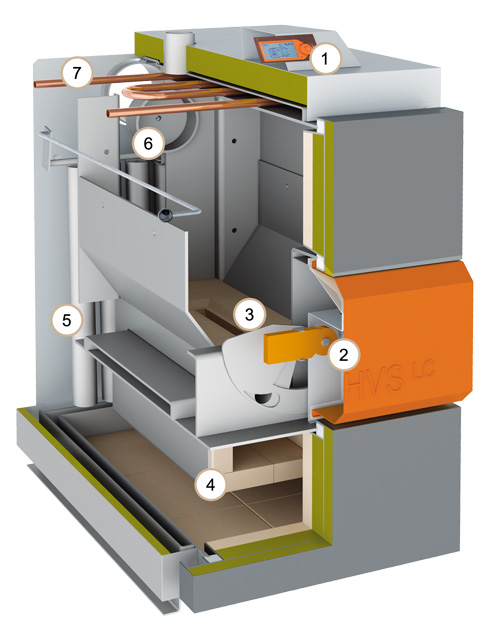

- Gasifying wood log boiler with downward combustion and upward wood gasification

- Solid boiler construction and robot manufacturing guarantee a long service life

- Consistent and certified boiler technology with innovational developments

- Easy handling and cleaning

- Up to 30% more effective combustible utilization than with standard wood log boilers

- modulation combustion, exhaust gas control (E/LC) as well as a lambda control unit (only LC)

The outstanding concept of the HVS boiler which has been further developed by permanent innovations has now reached the next generation. The permanently increasing environmental impact by dust and CO2 urges the industry on new developments and more modern technology in all areas. A modern and modular control concept of our wood log boiler series HVS LC ensures more performance and a low, environmentally friendly pollutant emission due to the serially integrated lambda sensor which observes permanently the exhaust gas values. With the help of the integrated boiler and exhaust gas logic the intelligent control recognizes the requirements of energy. Due to the modulating air supply the boiler is able to react to a possible power reserve and can therefore ensure an almost perfect exploitation of combustibles. This means the highest possible comfort for you and a steady and even combustion for your wood. You can only achieve an optimal efficiency factor with a perfectly aligned system. Therefore, we generally recommend our high quality stratification tanks SLS with integrated, patented, stratification system. The produced heat of the wood log boiler can be perfectly stored in this kind of tank. The stored thermal energy is relieved into the heating system when needed. This keeps your fuel consumption as low as possible and even preserves the environment.

The HVS LambdaControl is available in boiler sizes 16, 25, 40, 60 and 100 kW nominal heat output

The HVS Economic achieves very clean emission values even without lambda control. Due to the use of latest control technology a product was created which under-runs the already determined exhaust gas requirements. You can make the best possible use of the combustible with this boiler series and you also respect the environment. Each model is equipped with the electronic combustion control. The permanent observation of the exhaust gas and boiler temperature means perfect comfort for you and a steady and even combustion for your logs. The physics of the combustion process has been adopted from nature and integrated into our boilers in an excellent way. The logical cooperation of exhaust gas and boiler temperature in certain intervals is used to add the combustion air in an optimized way.

The HVS Economic is available in boiler sizes 25, 40, 60 and 100 kW nominal heat output

-

control unitgraphic display with permanent presentation of the system's operating status

-

forced draft fan and lambda actuatorthe quantity of air, necessary for a perfect combustion is supplied by the infinitely variable forced draft fan, equipped as standard. The secondary air is adjusted by the lambda sensor via a servo motor (only LC), depending on the emission values. With the boiler series HVS E the secondary air is adjustable via regulating screws.

-

ceramic nozzle with secondary air ductcreates the perfect gas mixture and guarantees a clean downward wood gas flame

-

slide-in combustion chamberwith high temperature resistant fireclay bricks for a complete burnout of the wood gases with a minimum of ash

-

exhaust gas heat exchanger with turbulatorsfor best possible hand-over of exhaust gas heat to the heating water

-

start-up flap with draft-barprevents outlet of flue gas when refueling the boiler

-

safety heat exchangerfor cooling down in case of overheating

| Measures and weight | type | 16 LC | 25 E 25 LC |

40 E 40 LC |

60 E 60 LC |

100 E 100 LC |

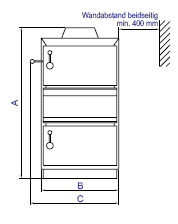

| A height | mm | 1135 | 1135 | 1370 | 1420 | 1420 |

| B width | mm | 590 | 590 | 590 | 760 | 760 |

| C width incl. slider | mm | 645 | 645 | 645 | 785 | 785 |

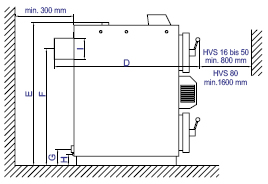

| D depth | mm | 840 | 1070 | 1070 | 1260 | 1650 |

| E height outlet | mm | 1075 | 1075 | 1310 | 1400 | 1400 |

| F height exhaust pipe (middle) | mm | 890 | 890 | 1110 | 1170 | 1170 |

| G height return | mm | 115 | 115 | 125 | 215 | 215 |

| H heigth draining | mm | 55 | 55 | 70 | 135 | 135 |

| Ø flue spigot | mm | 159 | 159 | 196 | 196 | 196 |

| Ø boiler flow line/ boiler return | Rp | DN 50 (2″) | DN 50 (2″) | DN 50 (2″) | DN 50 (2″) | DN 50 (2″) |

| Ø safety heat exchanger | G | DN 20 (¾″) | DN 20 (¾″) | DN 20 (¾″) | DN 20 (¾″) | DN 20 (¾″) |

| Ø immersion sleeve for safety heat exchanger | Rp | DN 15 (½″) | DN 15 (½″) | DN 15 (½″) | DN 15 (½″) | DN 15 (½″) |

| Ø draining | Rp | DN 15 (½″) | DN 15 (½″) | DN 15 (½″) | DN 20 (¾″) | DN 20 (¾″) |

| boiler weight | kg | 400 | 440 | 525 | 790 | 990 |

| fuel chamber/fuel consumption | type | 16 LC | 25 E 25 LC |

40 E 40 LC |

60 E 60 LC |

100 E 100 LC |

| permissible fuel | untreated, split wood log, residual moisture 16% ±3% |

|||||

| recommended wood log length | mm | 330 | 500 | 500 | 700 | 1000 |

| fuel chamber depth | mm | 370 | 560 | 560 | 750 | 1085 |

| fuel chamber height | mm | 490 | 490 | 750 | 730 | 730 |

| fuel chamber width | mm | 440 | 440 | 440 | 575 | 575 |

| dimension of the filling hole w/h | mm | 435/255 | 435/255 | 435/255 | 575/318 | 575/318 |

| fuel chamber capacity, volume liter approx. | L | 80 | 116 | 180 | 310 | 455 |

| max. filling weight (beech) approx. | kg | 20 | 30 | 48 | 80 | 120 |

| fuel consumption at nominal load (beech) approx. | kg/h | 4,5 | 7,1 | 11,2 | 17 | 25 |

| combustion period at nominal load (beech) approx. | Std. | 4,4 | 4,2 | 4,3 | 4,5 | 4,5 |

| Exhaust gas routing | type | 16 LC | 25 E 25 LC |

40 E 40 LC |

60 E 60 LC |

100 E 100 LC |

| recommended min. chimney cross section Ø | mm | 140 | 150 | 180 | 180 | 200 |

| draft requirements | Pa | 15 - 25 | 15 - 25 | 15 - 25 | 15 - 30 | 15 - 30 |

| effective minimum chimney height | m | approx. 7 | ||||

| exhaust gas mass flow | g/s | 10 | 16 | 25 | 38 | 64 |

| modulating exhaust gas temperature | °C | approx. 180 (±30) | ||||

| recommended exhaust gas routing | m | effective length < 1,5mtr (max. 2 bends) | ||||

| barometric damper | definitely recommended | |||||

| electrical data | Typ | 16 LC | 25 E 25 LC |

40 E 40 LC |

60 E 60 LC |

100 E 100 LC |

| mains voltage/frequency | V/Hz | 230/50 | ||||

| power consumption - standby | W | < 0,3 | ||||

| power consumption - operation (HVS E/LC) | W | 55 | 40/55 | 40/55 | 80/95 | 80/95 |

| hydraulic | Typ | 16 LC | 25 E 25 LC |

40 E 40 LC |

60 E 60 LC |

100 E 100 LC |

| min. buffer tank volume 1) | l | 1000 | 1500 | 2200 | 3300 | 5500 |

| manufacturer's recommendation 1) | l | 1500 | 2000 | 3000 | 5000 | 6000 |

| min. tube dimension (CU-/steel precision tube) Ø2) | mm | 28 | 28 | 35 | 42 | 54 |

| min. tube dimension (steel tube) 2) | DN 25 (1″) | DN 25 (1″) | DN 32 (1 ¼″) | DN 40 (1 ½″) | DN 50 (2 ″) | |

| required boiler return line temperature | °C | 70 | ||||